Among the various tests on products and materials, one of the least known to the general public is the dimensional testing.

The function of climatic tests and mechanical tests is easily understood even by non-experts: verifying the resistance of products and materials under certain conditions.

But what is the use of checking its dimensions?

Today we will try to explain it in simple words in our discussion of dimensional testing.

What is Dimensional Testing for?

There are sectors where the dimensions of the product are of vital importance and their precision must be maximum.

One above all: electronics. In fact, electronic components have very low margins of error in the manufacture of electronic boards, integrated circuits and other components.

To a lesser but still significant extent, the automotive sector is also involved in the dimensional test to verify the measurements of key engine components.

The same need for precision is required in other sectors such as the production of medical instruments and obviously the building industry.

In all these cases the manufacturer chooses some samples and subjects them to the dimensional test, performed internally or through external laboratories, so as to be able to certify that the production cycle complies with the required standards.

Perform

Extreme Testing

Discover the new series of Environmental Chambers for controlled climate testing

How the Dimensional Testing works

Dimensional Testing makes use of some technical tools that come into play depending on the nature of the sample to be checked.

Among the most technologically sophisticated are coordinate measuring machines (CMMs): instruments that employ a mechanical arm controlled by a computer to measure the dimensions of an object.

The object is placed on the work platform of the CMM and the mechanical arm moves along three axes to measure the object's x, y and z coordinates.

Another essential tool is the profile projector which is capable of measuring the dimensions of complex objects, such as curved surfaces, grooves or holes. The sample is placed on an illuminated table and a lens magnifies the image projected onto a graduated screen.

Other less complex instruments are used in dimensional testing such as goniometers, micrometers and calipers.

All these tests must be performed in accordance with the guidelines prescribed by a series of international standards among which we can mention: ISO 10012, ISO 14253 and ASTM E18.

Dimensional Testing and Climatic Chambers

Do climatic chambers play any role in the dimensional physical test?

Of course yes.

As in other tests on products and materials that we have already discussed, climatic tests play a complementary but fundamental role for the reliability of the results of a dimensional testing.

Especially for more delicate components, such as electronic boards and integrated circuits, it is essential to know how they behave when exposed to extreme environments, with high relative humidity rates or significant temperature changes.

For this reason, in many cases it is essential to integrate the dimensional control test with targeted climatic tests that certify the integrity of the sample in all conditions of use.

You cannot find the ideal chamber for your test?

Create your own environment, according to any test requirement

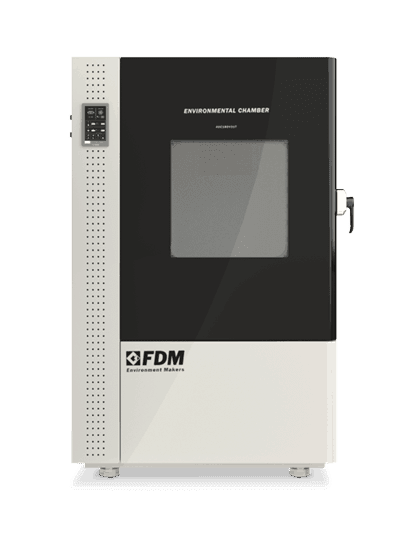

The FDM Environmental Chamber for Dimensional Testing

Electronics is the sector most involved in climatic tests complementary to the dimensional testing.

For this we recommend the FDM Environmental Chamber which, unlike the standard climatic chamber, specializes in so-called extreme climatic tests. Here, for example, we talked about the burn-in test in an environmental chamber.

For further doubts and questions, please do not hesitate to contact us.

Would you like to receive a quote or do you have questions about the product?

Contact us to receive more information about this Product.