In the summer of 2023, a tragic event shocked international public opinion.

On June 18, 2023, the Titan submarine disappeared in international waters. After days of research that kept the world in suspense, the hypothesis of an implosion due to pressure became more and more probable, until June 28, the day in which some debris from the vehicle was found, almost certainly confirming the implosion theory.

Many have criticized Ocean Gate, the company that manufactured the Titan, for not having sufficiently tested the submarine.

The tragedy demonstrated to the world how dangerous underwater pressure is and the need to design exploration vehicles for hostile environments, such as the ocean depths, with maximum safety.

Among the tests necessary for each vehicle of this type is the rapid decompression test.

What is Rapid Decompression for?

As the Titan accident demonstrated, sudden changes in pressure can be lethal not only to people, but also to vehicles designed to keep the crew in controlled atmospheres, causing irreparable damage to the structure.

Rapid decompression is therefore an eventuality that the structures of two types of vehicles must be able to resist: aircraft and submarines.

Both airplanes and submarines experience rapid changes in pressure, which become even more sudden in emergency situations, such as the need for a sudden ascent or an emergency landing.

The rapid decompression test serves to test all the structural components of a vehicle in order to demonstrate that it can resist sudden changes in surrounding pressure.

Perform

Extreme Testing

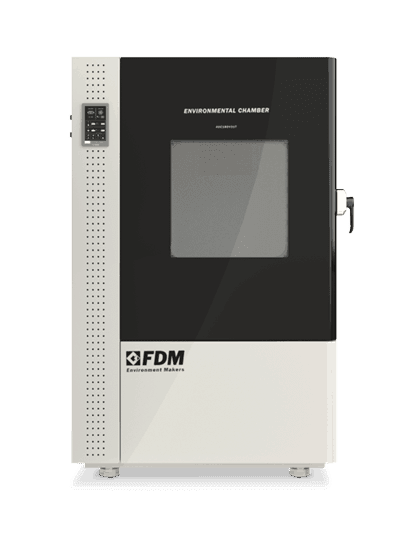

Discover the new series of Environmental Chambers for controlled climate testing

How the Rapid Decompression Test works

The rapid decompression test aims to simulate in a controlled environment the real conditions encountered by vehicles experiencing rapid and sudden changes in atmospheric pressure.

To perform the test, laboratory instruments such as rapid decompression chambers or altitude chambers are used.

These chambers are isolated environments in which it is possible to alter the atmospheric pressure values at will, reaching very high levels at both extremes.

Both external and internal components and entire vehicles are tested in the decompression chambers, which must withstand a series of tests precisely outlined in a series of international standards which will lead to the relevant certifications.

As far as aeronautics is concerned, one of the most complete standards is DO-160 which, in addition to pressure tests, also outlines the verification procedures for other environmental factors, such as temperature and relative humidity.

You cannot find the ideal chamber for your test?

Create your own environment, according to any test requirement

The FDM Environmental Chamber for the Air Force

We have seen that rapid decompression is not the only test that aircraft and submarine components must pass.

In fact, in addition to pressure, at high altitudes and in the depths of the sea, temperature and relative humidity also reach extreme values and are subject to sudden changes.

FDM environmental chambers are laboratory instruments specialized in these so-called "extreme" climatic tests, due to the very high values required by the procedures.

Do not hesitate to contact us to find out more.

Would you like to receive a quote or do you have questions about the product?

Contact us to receive more information about this Product.