Are there microscopic particles inside the electronic devices you use that can affect their functioning?

You've probably never asked yourself this question.

Luckily, there are those who make them for you.

Today we talk about the PIND Test, i.e. the Particle Impact Noise Detection Test.

What is the PIND Test for

For the uninitiated it may seem strange, but a frequent cause of malfunctioning of electronic devices - especially in extreme environments - is due to the contamination of the circuits by microscopic particles.

These microscopic particles can be of various nature and have different origins:

- Manufacturing residues: These are residues of materials such as adhesives, solvents, resins, lubricants and thermal paste.

- Environmental Contamination: Dust, fibers, hair, and other contaminants that entered the device during assembly.

- Device wear: device wear can also cause damage that allows solid particles to enter the circuits.

The PIND test has the purpose of verifying the presence of these microscopic particles within a device under examination.

Perform

Extreme Testing

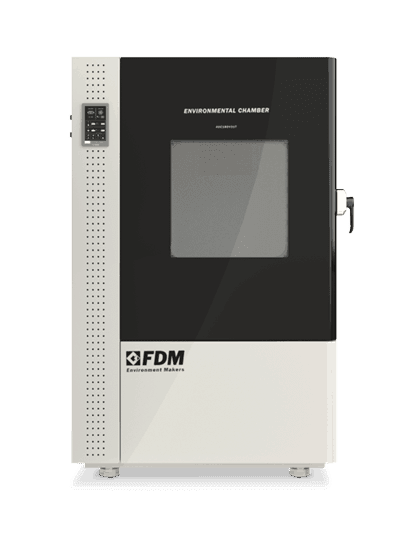

Discover the new series of Environmental Chambers for controlled climate testing

How the PIND Test Works

The PIND Test is performed by introducing certain particles of known size into the device or electronic component and exposing it to physical or electrical vibrations.

When the particles are hit, they emit sounds which are recorded by a highly sensitive microphone, thus revealing the presence of other foreign particles within the sample to be tested.

The PIND Test is performed in an isolated and controlled environment which is also able to simulate the real conditions of use of the device in question.

Depending on the final uses of these devices, the environment can be a thermal vacuum chamber, a pressure chamber or even a climatic chamber.

Which Sectors are involved in the PIND Test

More than consumer electronics, the PIND Test concerns two sectors in which electronic components are subjected to severe stress and unconventional environments: the aerospace and military industries.

The main international standards that regulate the PIND Test are in fact the MIL-STD-750 Method 2052 and MIL-STD-883, Method 2020, both of a military nature.

PIND Test and Climatic Chambers

As we have anticipated, the PIND Test must be carried out in isolated environments in which it is possible to control certain parameters to simulate the actual environmental conditions of use of the device.

For this reason, climatic chambers play a complementary role in the PIND Test to keep the behavior of the device under control at certain temperature and humidity values, which can also reach extreme thresholds.

You cannot find the ideal chamber for your test?

Create your own environment, according to any test requirement

The FDM Environmental Chamber for PIND Test

The FDM Environmental Chamber is the ideal tool for carrying out climatic tests complementary to the PIND Test as it is designed to reproduce extreme environmental conditions.

In fact, it can reach -70°C and +180°C in temperature and up to 98% relative humidity.

For further doubts and questions, please do not hesitate to contact us.

Would you like to receive a quote or do you have questions about the product?

Contact us to receive more information about this Product.