All the products and materials that surround us are continuously exposed to various environmental stressors.

For this reason, environmental stress tests are used far and wide in various industries to evaluate how materials react to conditions such as humidity, extreme temperatures, sudden changes in temperature or humidity and much more.

In the following article we will delve into Environmental Stress Testing, how many types there are, the industries involved and the tools to conduct it.

How Environmental Stress Testing is Conducted

Environmental stress testing can be conducted in two main ways, known as HALT (Highly Accelerated Life Test) and HASS (Highly Accelerated Stress Screen). Both focus on how products react to extreme environmental conditions, but they do so with different objectives and methods

- HALT (Highly Accelerated Life Test) Test: The goal of a HALT is to identify the resistance limits of products, exposing them to extreme temperature and humidity conditions to identify the points of failure. During these tests, materials are subjected to rapid and intense temperature changes (such as cycling between extreme heat and freezing cold) and high humidity levels. The conditions are taken well beyond the normal operating parameters of the product, to identify critical points and improve the design. The HALT test is especially useful in the development phase, to gain insights into the product's strength margins and potential failure points. d

- HASS (Highly Accelerated Stress Screen) Test: Unlike HALT, the HASS test is used on products that are ready for production, and its aim is to detect any manufacturing defects or compromised materials. Here too, climate cycles with extreme temperatures and humidity are used, but with more moderate parameters than HALT, so as not to damage the products but to ensure that they function correctly within the specified operating limits. The HASS test allows you to uncover hidden defects that could emerge in real-world conditions and helps ensure that only reliable products reach the market.

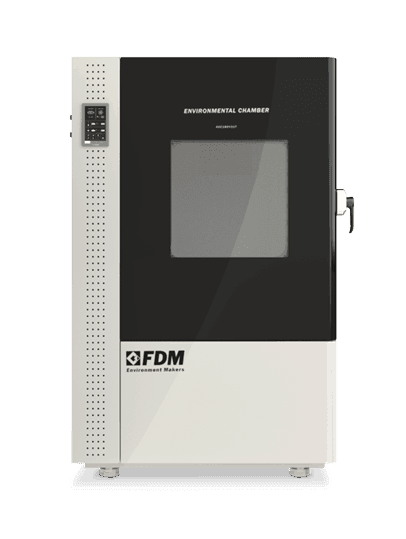

These tests are performed inside environmental chambers.

Environmental chambers are laboratory instruments designed to precisely replicate and control climatic conditions, such as temperature and humidity. These chambers allow you to monitor the reactions of products in real time, ensuring the ability to promptly identify any critical issues or defects.

Perform

Extreme Testing

Discover the new series of Environmental Chambers for controlled climate testing

Which Industries Are Involved in Environmental Stress Testing

Considering the universality of environmental stress, there are many sectors involved in environmental stress testing.

- Aerospace and Defense: These sectors must ensure that electronic and structural components can operate in extreme environments. The procedures are outlined in MIL-STD-810.

- Automotive: Car manufacturers use environmental tests to ensure that vehicle components remain performing under variations in temperature, humidity and vibration, in compliance with standards such as ISO 16750.

- Electronics: Both consumer electronics and components are subjected to a very rigorous series of tests to certify the optimization of performance in all environmental conditions. In this area, IEC 60068 is one of the main references for environmental robustness tests.

You cannot find the ideal chamber for your test?

Create your own environment, according to any test requirement

The FDM Environmental Chamber for Environmental Stress Testing

FDM environmental chambers are an ideal solution for those who want to conduct reliable and precise environmental stress tests.

Thanks to the stillFACE controller and the revoFACE programmer, our environmental chambers can conduct all the tests listed above, assisting the operator in all phases of the procedure.

FDM - Environment Makers has been a leading company in the environmental testing sector for over 70 years. Our technicians are also available to interface with the customer to design an instrument suitable for their needs.

For further doubts and questions, please do not hesitate to contact us.

Would you like to receive a quote or do you have questions about the product?

Contact us to receive more information about this Product.