On these pages, we often deal in detail with individual climate tests aimed at verifying the conformity of materials and products.

Often, however, tests on products and materials are not performed individually but organized in protocols that aim to examine every possible weakness of a given sample.

This is the case with DPA Testing.

What is DPA Testing for

As we have said, DPA Testing is more than a test but a protocol, that is a set of tests of various types to be performed in succession on a sample to verify its resistance to all the factors that could undermine its functioning.

DPA stands for Destructive Physical Analysis, to testify to the intensity of the stresses to which the sample will be subjected.

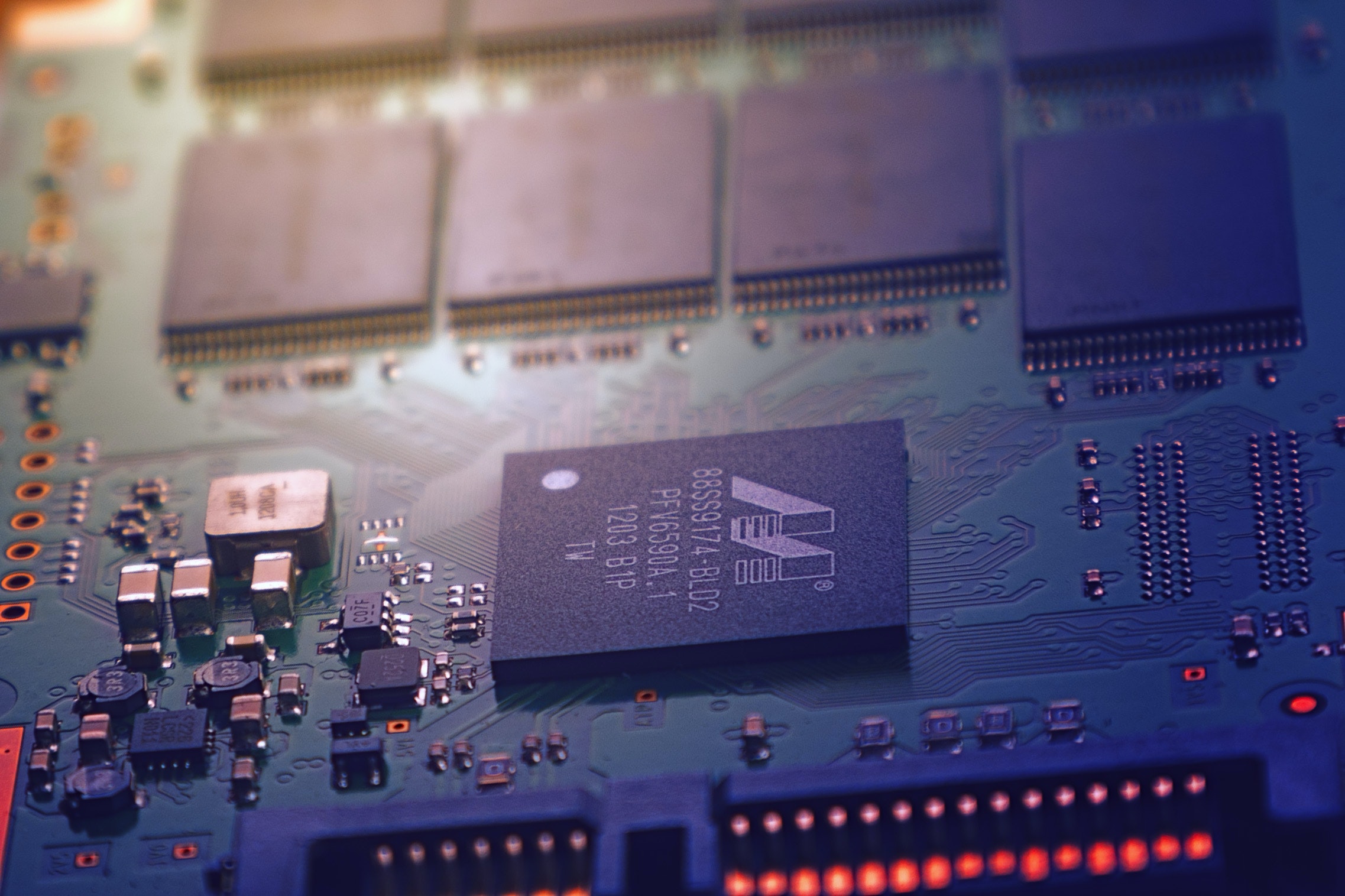

DPA Testing mainly concerns the military and aerospace sector and, more precisely, the sophisticated electronic components that are used in this field.

The rigorous tests that make up the DPA Testing protocol serve to avoid the so-called "infant mortality" of electronic components which is one of the main problems faced by the production of such delicate devices.

Performing the DPA Testing prevents faulty components from reaching the assembly phase and, at the same time, recurring malfunctions are identified which will then be addressed in the design phase.

Perform

Extreme Testing

Discover the new series of Environmental Chambers for controlled climate testing

How DPA Testing works

As we have said, DPA Testing is a protocol consisting of a wide variety of tests that must avoid any type of malfunction that electronic components may encounter.

For the number and type of tests, reference is generally made to the standards produced by the MIL-STD, namely the United States Military Standard.

The standards that affect the DPA Testing are: MIL-STD-883, MIL-STD-1580B, MIL-STD-750E, MIL-STD-202G.

As can be seen from MIL-STD-883, the tests that make up the DPA Testing can be divided into four categories: environmental tests, mechanical tests, digital electrical tests and linear electrical tests.

Among the tests that are part of the category of environmental tests, we find various procedures that we have already dealt with on these pages such as the Burn-In Test on electronic boards.

You cannot find the ideal chamber for your test?

Create your own environment, according to any test requirement

The FDM Environmental Chamber for DPA Testing

To perform the entire first test part of the DPA protocol, that is the environmental tests, there is no better tool than an environmental chamber.

Among the climatic chambers, the environmental chambers are the most used in the military and aerospace sectors because they specialize in the so-called extreme tests: climatic tests that reach very high values of temperature and relative humidity.

The FDM environmental chambers have a temperature range between -70 / 180 °, and a relative humidity regulator that reaches 98 °.

Our environmental chambers also implement the innovative revoFACE programmer, ideal for dynamic tests involving electronic components.

For further doubts and questions, please do not hesitate to contact us.

Would you like to receive a quote or do you have questions about the product?

Contact us to receive more information about this Product.