More than in any other era, today we are surrounded by batteries. Batteries power a wide range of devices, from cell phones to electric cars.

To ensure their safety, efficiency and durability, batteries are subjected to a series of very rigorous tests, outlined by internationally recognized bodies.

Today we talk about the main battery testing standards, explaining what they are for and why they are important.

What are Battery Tests and what are they for?

Before talking about battery testing standards, let's briefly look at what these tests are.

Battery testing is a series of procedures that aim to evaluate the performance, safety and durability of batteries. Depending on the type of stress to which I subject the battery, these tests can be divided into environmental tests, mechanical tests and electrical tests.

Their purpose is to identify any manufacturing defects that could cause malfunctions or, worse, accidents such as explosions or fires. In addition to this, many of these tests verify performance and functionality, i.e. the battery's ability to maintain an adequate charge over time, thus ensuring that powered devices can operate reliably.

Perform

Extreme Testing

Discover the new series of Environmental Chambers for controlled climate testing

The Main Battery Testing Standards

There are several battery testing standards, each focusing on specific aspects of their performance and safety. Here are the main standards for battery testing:

The IEC 62133 test, developed by the International Electrotechnical Commission (IEC), covers the safety of rechargeable lithium-ion and nickel-ion batteries. The test aims to verify the batteries' resistance to conditions such as short-circuiting, overcharging, over-discharging, and high temperatures, ensuring that they can operate safely under various stress situations.

The UN 38.3 test, issued by the United Nations (UN), is mandatory for air, sea and land transport of lithium batteries. The test ensures that the batteries can withstand the physical and environmental stresses typical of transport, such as vibrations, shocks, altitude pressure and extreme temperatures, reducing the risk of accidents during transport.

The ISO 12405 test, developed by the International Organization for Standardization (ISO), is specifically applied to electric vehicle batteries. The object of the procedures is to verify the performance, durability and safety of batteries in conditions of daily use and in stressful situations, such as rapid charging and discharging cycles, ensuring that they can provide reliable performance in electric vehicles.

Finally, the IEC 60086-4 test, another IEC standard, is specifically outlined for primary (non-rechargeable) batteries. Its procedures serve to verify the safety of batteries under conditions of abnormal discharge, short circuit and high temperatures, ensuring that they can function in so-called extreme conditions.

Finally, the IEC 60086-4 test, another IEC standard, is specifically outlined for primary (non-rechargeable) batteries. Its procedures serve to verify the safety of batteries under conditions of abnormal discharge, short circuit and high temperatures, ensuring that they can function in so-called extreme conditions.

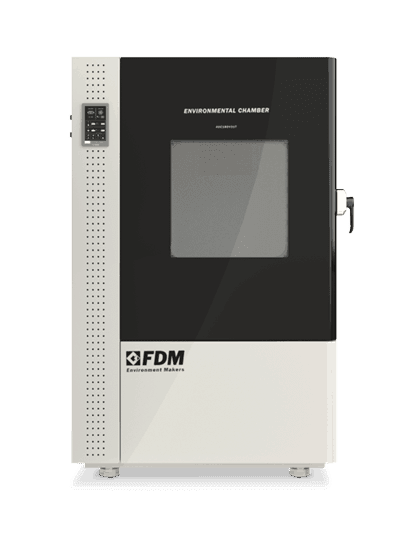

The Environmental Chamber for Battery Testing

Within the battery testing standards listed above, several procedures aim to verify the performance of batteries under certain environmental conditions.

To carry out all environmental tests on batteries it is necessary to have an environmental chamber.

The environmental chamber is part of the family of climatic chambers and is specialized in so-called "extreme" tests, i.e. those which reach high temperature or relative humidity values. For this reason, environmental chambers are the ideal tool for carrying out environmental tests on batteries which often have to reach these high values

You cannot find the ideal chamber for your test?

Create your own environment, according to any test requirement

The FDM Environmental Chamber in accordance with Battery Testing Standards

For over 70 years, FDM - Environment Makers has been a leading company in the production of climatic chambers.

Our Environmental Chambers are equipped with the most modern technologies that assist the operator in all phases of the procedure and are approved for the battery test standards listed above.

Furthermore, FDM environmental chambers can be approved to EUCAR hazard level standards, up to the sixth level.

For further doubts and questions, please do not hesitate to contact us.

Would you like to receive a quote or do you have questions about the product?

Contact us to receive more information about this Product.