Each laboratory test must guarantee the reproduction of standard conditions to obtain constant and reliable results.

Testing fixtures are those tools that guarantee the stability of the tested sample and, as we will see, they are a very broad category of objects.

Mechanical Testing Fixtures and others.

Even talking about objects is misleading when it comes to testing fixtures.

The concept of testing fixtures is very common in computer science where it describes a particular type of software and/or a set of procedures designed to test a computer system with well-defined starting conditions.

As for the tests on products and materials, a testing fixture is a concrete object that physically holds the sample to be tested in the test area.

Also among the mechanical testing fixtures, there are considerable differences depending on the shape and the purpose of the fixture itself.

Perform

Extreme Testing

Discover the new series of Environmental Chambers for controlled climate testing

Mechanical Testing Fixtures, Bending Fixtures, and Climatic Fixtures.

Much of the test fixtures are made up of mechanical testing fixtures and bending fixtures.

These are essential components for the universal test machines we covered in this recent article.

They are clamp devices that hold the samples in place during the tests and among these we can mention 3-point and 4-point Bend Fixtures and various types of Wedge Grips, some of which are designed to withstand very high temperatures and be used inside the environmental chambers for some climatic tests.

Another point of contact between testing fixtures and climatic tests concerns the electronics and specifically the burn-in tests.

A Concrete Example: Testing Fixtures in the Burn-In Test

The burn-in test is a phase of testing an electronic board. It is a test that short-circuits all the components of the board through climatic stress. The test temperature must be carefully controlled, not to be too high and burn the chips, but high enough to simulate particular conditions.

We have dealt with it in detail in this article.

To perform this type of test in the best possible way, the electronic board must be placed on particular fixings, namely the testing fixtures, capable of withstanding high temperatures and which support the board in the correct way.

You cannot find the ideal chamber for your test?

Create your own environment, according to any test requirement

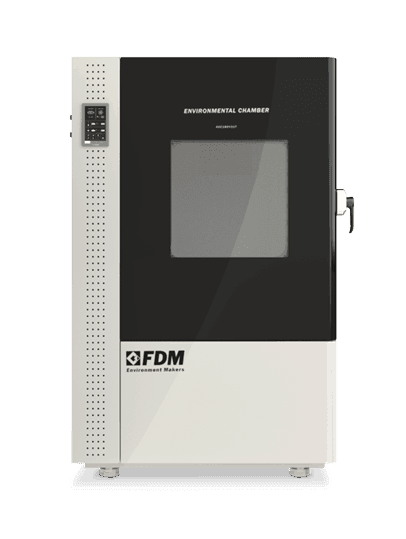

The FDM Environmental Chamber

An environmental chamber is required to perform extreme climatic tests on electronic boards.

The FDM environmental chamber has a temperature range from -70 ° C up to + 180 ° C and can be equipped with different sized testing fixtures to perform a wide range of climatic tests on products and materials.

Thanks to the innovative stillFace controller, using an FDM environmental chamber is simple and intuitive, while also ensuring the reliability of the results.

For further needs, please do not hesitate to contact us.

Would you like to receive a quote or do you have questions about the product?

Contact us to receive more information about this Product.