In the world of product and material testing, the adoption of international standards is crucial to ensure quality, safety and compatibility in an increasingly globalized world.

For this reason, there are several international bodies that issue standards and guidelines intended for manufacturers, in order to outline shared testing procedures and issue related certifications.

The IEC, i.e. the International Electrotechnical Commission, is one of these and among the oldest.

In today's article we will look at the history of IEC standards, their current role and which standards influence environmental testing in particular.

History of the IEC

The International Electrotechnical Commission (IEC) was founded in 1906 as the result of a debate that began six years earlier at the Paris International Electrical Congress which saw the participation of national technical commissions from various countries united in the effort to establish an internationally recognized body for standardization in the field. electrical engineer.

Since its inception, the IEC has been committed to designing and promoting global standards dedicated to a wide range of electrical and electronic technologies. These procedures are mainly aimed at manufacturers of both components and consumer electronics.

Perform

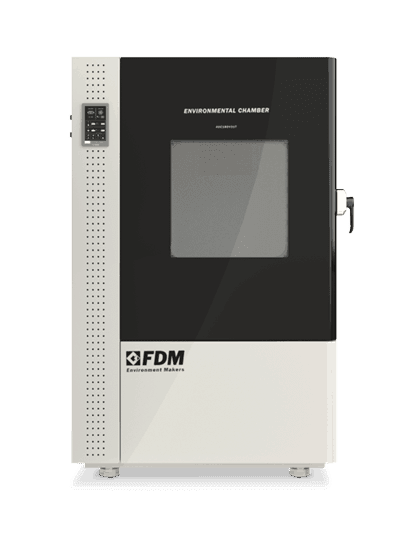

Extreme Testing

Discover the new series of Environmental Chambers for controlled climate testing

What is the IEC for today

Today, the IEC is among the most important international standards organizations and by far the most important for the electronics sector.

Over 170 countries adopt and recognize IEC standards, and their ramifications cover a broad spectrum of industries, including energy, telecommunications, industrial automation and consumer electronics.

By developing increasingly precise and rigorous testing of products and materials, IEC standards globally increase the safety, efficiency and compatibility of electronic products and devices.

gli standard IEC incrementano globalmente la sicurezza, l'efficienza e la compatibilità dei prodotti e dei dispositivi elettronici.From a manufacturer's perspective, IEC standards also help companies reduce production costs and overcome trade barriers, ensuring that their products can be used and accepted globally.

Environmental Tests of IEC Standards

On these pages we mainly deal with environmental tests carried out in climatic chambers.

In electronics, both components and consumer electronics, environmental tests are of crucial importance to evaluate the efficiency and reliability of such delicate products in all environmental conditions.

Let's see what the main environmental tests we find in the IEC Standards are.

- Humidity and heat test (IEC 60068-2-30):

Relative humidity and temperature are the main parameters of every climate test. The humidity and heat test involves various cycles of exposure of the sample to different parameters, in order to evaluate how the materials and components resist corrosion and deterioration. It is especially important for electronic devices used in tropical or humid environments.

- Low temperature test (IEC 60068-2-1): (IEC 60068-2-1):

Extreme cold is just as much of a problem as heat for many devices. This procedure exposes the sample to extremely low temperatures. It is essential for equipment used in cold climates or for aerospace applications.

- Thermal shock test (IEC 60068-2-14):

Not only extreme values

For this purpose there is the thermal shock test. We talked about it in depth here.

- Sunlight exposure test (IEC 60068-2-5):

This test evaluates the resistance of materials and components to prolonged exposure to sunlight, technically called solar radiation, simulating the effect of UV rays and heat. It is fundamental for all electronics that are permanently outdoors during their life cycle.

You cannot find the ideal chamber for your test?

Create your own environment, according to any test requirement

The FDM Environmental Chamber according to IEC Standards

We have seen that most environmental tests on electronics involve exposure to extreme conditions.

For this reason there is no better tool for carrying them out than the environmental chamber. The environmental chamber is that type of climatic chamber specialized in extreme climatic tests, i.e. those which touch significant values

FDM environmental chambers are capable of performing all of the above tests in accordance with the procedures outlined in the IEC Standards.

Write to us to find out more.

Would you like to receive a quote or do you have questions about the product?

Contact us to receive more information about this Product.