Environmental testing is essential for evaluating the resistance and durability of products and materials exposed to adverse climatic conditions.

Many industries, such as food, pharmaceutical, electronics and manufacturing, use these tests to ensure that their products are safe and perform even in extreme environments. There are different types of environmental tests.

In the following article we will analyze the most common ones performed in a climatic chamber.

Perform

Extreme Testing

Discover the new series of Environmental Chambers for controlled climate testing

Types of Environmental Testing: Temperature and Humidity

The temperature and humidity test is one of the fundamental environmental tests and is used to determine the durability of products subjected to variable environmental conditions. It is of particular importance for sectors such as food and pharmaceutical, where the stability of products on the shelf is essential for consumer safety and regulatory compliance.

These tests are regulated by internationally recognized standards such as ICH Q1A and we have discussed them in detail here.

Types of Environmental Test: Thermal Shock

The thermal shock test is used to evaluate the impact that sudden and drastic changes in temperature have on products and materials.

It is therefore of vital importance for all those objects that, during their life cycle, can be exposed to extreme variations in temperature in very short times. The environmental chambers used for thermal shock allow a product to be quickly transferred from a very hot to a very cold environment, verifying its ability to maintain structural integrity.

We have discussed it in detail here.

Perform

Climate Stress

Discover the new series of Climate Chambers for controlled climate testing

Types of Environmental Test: Burn-in Test

Fundamental in electronics, the burn-in test is one of the most rigorous environmental tests and is commonly used to test electronic boards and printed circuit boards.

During the burn-in test, the component is exposed to extreme operating conditions (for example, high temperatures) for prolonged periods in order to identify any manufacturing defects or problems that could cause premature failure.

We have dedicated an entire article to the Burn-In Test that you can read here.

You cannot find the ideal chamber for your test?

Create your own environment, according to any test requirement

Types of Environmental Test: Sunlight

Not only temperature and relative humidity.

With appropriate accessories such as professional sets of UV lamps, climatic chambers can also simulate sunlight.

This test is crucial for products intended for outdoor use, such as garden furniture, building or vehicle cladding, since continuous exposure to UV rays can cause fading, deterioration or loss of physical properties.

The ISO 4892-2 standard regulates methods of exposure to artificial sunlight in controlled environmental conditions. We have discussed it in more detail here.

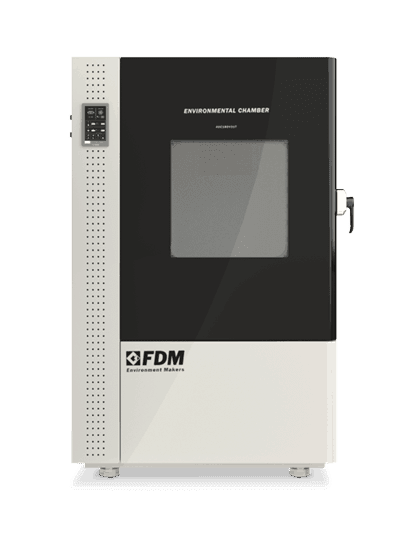

The FDM Climatic Chamber

The Climatic Chambers of FDM - Environment Makers can perform all the types of environmental tests discussed above and many more.

Furthermore, thanks to our stilFACE controller and the innovative revoFACE programmer, our instruments assist the operator in all phases of the procedure.

For further needs, please do not hesitate to contact us.

Would you like to receive a quote or do you have questions about the product?

Contact us to receive more information about this Product.