All the products and materials that surround us in everyday life must be subjected to a rigorous series of tests to ensure our safety but there are sectors in which it is more vital than in others. The aerospace sector is one of these and for two reasons.

Firstly because the environmental conditions that vehicles and their components must withstand are extreme to say the least. And secondly because a malfunction in this field can have very serious consequences.

In the aerospace sector, safety and reliability are essential and today we are dealing with the tests that concern the components.

Aerospace component testing are of various nature and concern all the components, mostly electronic, that are used in space vehicles, satellites and aircraft.

Today we will discover what the main tests for aerospace components are with particular attention to the environmental ones.

Types of Aerospace Component Testing Procedure

There are dozens and dozens of aerospace component tests, each with a specific purpose. However, they can be divided into three macro-categories: Environmental Tests, Structural Integrity Tests, Electrical and Functional Tests.

Let's see them in detail now.

- Environmental tests: They reproduce extreme conditions of temperature, humidity and pressure. For example, thermal cycle tests simulate rapid temperature variations to verify the expansion and contraction of materials.

- Structural integrity tests: They verify resistance to mechanical stress. For example, the static load test evaluates how a component withstands forces greater than those expected during the mission.

- Electrical and functional tests: They check the correct functioning of electronic systems. Among these, the continuity test verifies the integrity of the connections, while the insulation test detects any electrical leaks.

Perform

Extreme Testing

Discover the new series of Environmental Chambers for controlled climate testing

Aerospace Component Testing: Environmental

Among aerospace component testing, environmental tests are particularly important because the environments that vehicles and their components will have to face are extreme.

The tests simulate these conditions, such as those that occur during launch, at high altitude or in space.

Among the most important is for example the High-Temperature Performance Test, aimed at evaluating the behavior of components at high temperatures.

The test is performed using a laboratory instrument called an environmental chamber.

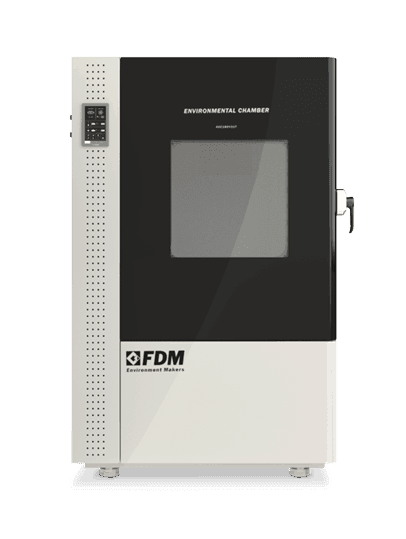

The environmental chamber is part of the family of climatic chambers, that is, hermetically insulated rooms inside which it is possible to alter and monitor the temperature and relative humidity. We call environmental chambers the types of chambers specialized in extreme tests, that is, which reach very high values

In fact, among the protocols of the High-Temperature Performance Test there are thermal cycles that reach 150° and are used to verify that the expansion and contraction of the component materials are within acceptable ranges.

These and other environmental tests are regulated by internationally recognized organizations that produce standards in which the procedures are outlined.

Among the most widespread we find:

- MIL-STD-810: Military standard for environmental tests.

- RTCA DO-160: Standard for high altitude environmental conditions

- ECSS-E-ST-10-03C: European Standard for Aerospace Environmental Testing.

You cannot find the ideal chamber for your test?

Create your own environment, according to any test requirement

The FDM Environmental Chamber for Aerospace Component Testing

For over 70 years, FDM - Environment Makers has been a leader in the climate testing sector.

FDM environmental chambers are the ideal solution for performing environmental tests on aerospace components. Designed to ensure maximum precision, they simulate a wide range of extreme conditions and can be easily programmed for rapid thermal cycling thanks to our innovative revoFACE programmer that assists the operator in all phases of the procedure.

For further needs, please do not hesitate to contact us.

Would you like to receive a quote or do you have questions about the product?

Contact us to receive more information about this Product.