Among the various atmospheric conditions for which products and materials must be tested, high altitude conditions occupy a special place.

The high altitude simulation test is in fact essential for some sectors and must be performed with precise laboratory instruments.

In today's article we will delve into the high altitude simulation test, its strengths but also its limitations and, therefore, the need for complementary tests.

What is the High Altitude Simulation Test

The High Altitude Simulation Test (often abbreviated with the acronym HAST) is a procedure performed in a controlled environment where it is possible to simulate high altitude atmospheric conditions, characterized by two main factors: low atmospheric pressure and very cold temperatures.

High altitude simulation chambers are designed precisely for this purpose. Inside them it is possible to precisely regulate, alter and monitor the temperature and atmospheric pressure.

Perform

Extreme Testing

Discover the new series of Environmental Chambers for controlled climate testing

What is the High Altitude Simulation Test For

Many products and materials may require high altitude simulation testing, but the sectors most involved are two: aerospace and automotive.

Space vehicles, airplanes but also cars -with their respective differences- must demonstrate that they can function even in extreme atmospheric conditions such as those found at high or very high altitudes.

Particular attention must be paid to the electronic components of these vehicles which must maintain high performance in any type of environment.

Among the internationally recognized standards that outline the procedures for high altitude simulation testing we find the MIL-STD-810G - Method 500.5, a US military standard that specifies the procedures for testing equipment intended to operate in extreme conditions, including high altitudes; the RTCA DO-160 which complements it in civil aeronautics and the ISO 2669:2009 which covers all tests on aircraft including high altitude.

Other Extreme Environmental Tests

Although they are fundamental factors, low atmospheric pressure and very cold temperatures do not exhaust the spectrum of environmental conditions that vehicles in the aerospace and automotive sectors must face.

Specifically, it is necessary to subject both vehicles and their components to significant and sudden temperature variations, both uphill and downhill, and to the relative humidity levels.

Extreme climatic tests as a whole are therefore necessary to guarantee safety and performance in the sectors mentioned above.

For this reason, in addition to the high-altitude simulation chamber, an environmental chamber must be equipped.

You cannot find the ideal chamber for your test?

Create your own environment, according to any test requirement

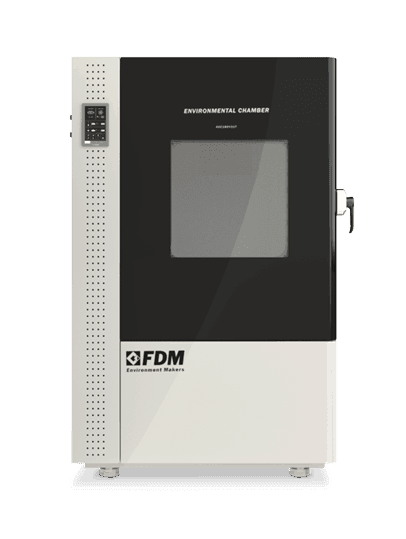

The FDM Environmental Chamber for Extreme Climatic Tests

The environmental chamber is a particular type of climatic chamber specialized in so-called extreme climatic tests. In this type of chamber, it is possible to reach extreme temperature values, both high and low, and relative humidity levels close to saturation. The environmental chamber also offers more precise and detailed control of these variables and the possibility of setting thermal cycles, which can be equally critical for the durability of materials.

The FDM - Environment Makers environmental chamber has a temperature range from -70°C to +180°C and relative humidity levels from 10% to 98%.

In addition, thanks to the innovative revoFACE programmer it is possible to set dynamic tests and thermal cycles with precision and safety.

For further needs, please do not hesitate to contact us.

Would you like to receive a quote or do you have questions about the product?

Contact us to receive more information about this Product.