What is Frost Heave

Frost heaving (or frost heave) is a natural phenomena through which, in freezing conditions, soil swells up, as temperatures penetrate into it and ice grows upwards.

The ice crystals growth is restrained by the soil but that is not enough to contrast the formation of lenses within the soil itself.

The lenses bind together with it and turn into a strong solid block that heaves the ground. This is what causes frost heave.

Normally the strength increases as the temperature is lowered.

This eventually damages roads and buildings, at a rate according to the type of soil and its moisture content.

Leading researchers such as Konrad, Morgenstern and Penner have studied frost heaving through various laboratory test methods, in order to closely analyze the phenomenon.

Over time, some of the most important research centers around the world have proposed standardized test methods for research laboratories.

This is to guide them to better analyze what is frost heave and what is frost heave test.

Major references are to be found at the following links:

- TRRL (Transport and Road Research Laboratory) in the UK

The British Standard Institution, also in the United Kingdom (BS 812-124:2009)

The ISO (International Organization for Standardization) with the ISO 13793:2001 standard

How to Prevent Frost Heave

Preventing frost heaving is not easy.

An important customer of ours informed us about the issue of performing this type of test, because of the unavailability on the market of frost heave test equipment.

That is why at FDM we developed a machine that could automatically perform the frost heave test, simulating real environmental conditions.

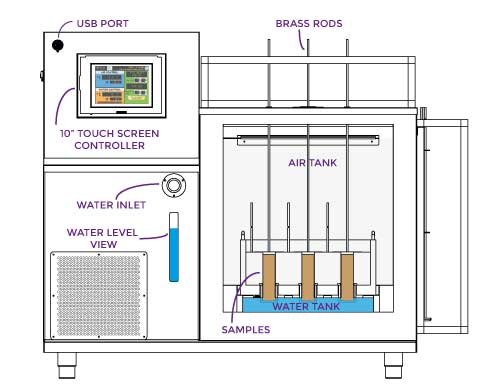

The FDM SRU Frost heave chamber (FHU812) was developed according to the British standard BS 812-214.

It is composed by two different parts: a temperature-controlled element and a second environment where all the power and control components for the machine functioning are contained.

The temperature-controlled part is divided into two tanks:

- A lower tank containing water at 4°C temperature

- An upper tank containing refrigerated air at -17°C.

The tanks are independent from each other: In between the tanks, there is an intermediate cradle and a wooden support containing the samples to be tested.

The chamber also comes complete with a datum reference frame and 9 brass bars.

The 9 bars correspond to the 9 specimens that make the brass bars rise, by capillary freezing.

fig1. FHU812 frost heave test equipment composition

How the FDM SRU Machine Works

The FDM SRU machine works exactly as a simulation of the natural phenomena, thus imitating the freezing of the soil.

The water from the temperature-controlled environment rises and freezes so to raise the bars.

The operator should measure every 24h how much bars raised. Measuring the lifting of each bar will then mean measuring the lifting of each sample.

The machine is equipped with a touch screen that automates most of the frost heave testing.

The user must load the chamber with the samples, install the reference frame, insert the brass rods and then start the test through a button on the touch screen.

The machine will take care of the rest by advising the user whenever it is required to check the frost heave.

At the end of the test, it is possible to remove the USB key and download all data from the eleven probes installed in the test volume onto a PC.

Download the Datasheet of this Test Chamber

How we Facilitate your Tests

At FDM we are constantly looking for solutions to improve environmental tests in order to facilitate scientific researchers with efficient, reliable and above all customized machinery for every type of use.

In this specific project, we were able to help a researcher who needed to simplify his testing process.

The operator revealed us that final results were optimal.

The SRU has accelerated his testing process by 60%, compared to its previous methods, and allowed him to obtain more reliable values.

In FDM we care about our customers and we evaluate all requests and testing requirements coming from them, even in cases of single customized machines.

Contact FDM you will have immediate answers on feasibility and costs for your projects, with maximum transparency and professionalism, for over 70 years.