The laws that regulate the compression tests of building materials, such as asphalt, are constantly being updated. The literature that regulates these tests is subject to continuous revisions, since the requirement to put products on the market that maintain their properties unaltered in all conditions, is directly linked to the construction quality of the roads, hence to people's safety.

Perform

Extreme Testing

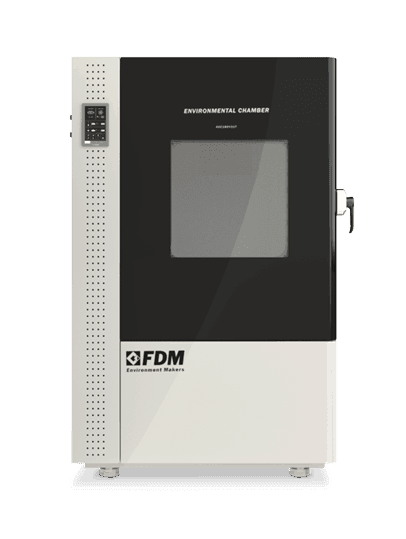

Discover the new series of Environmental Chambers for controlled climate testing

The most important regulations to consider, in particular with regard to bituminous conglomerates, are the following:

- AASHTO TP10-1993

- AASHTO T 314-12

- ASTM D8044

- USED AASHTO TP124

- AASHTO TP105-13

- AASHTO T 314-12

- EN 12697-46:2012

- ASTM D7313 - 07A

Concrete compression test in compliance with the regulation

An important Italian partner, a retailer of temperature and/or humidity controlled concrete compression tests, informed us of his requirement to supply a press that could comply with the evolution of the laws, without necessarily having to be replaced after each regulatory update.

Since there were no standard solutions on the market that could overcome this problem, and to also include the opportunity to have modifiable technical specifications, the customer decided to turn to FDM, the ideal solution for customized projects of any kind.

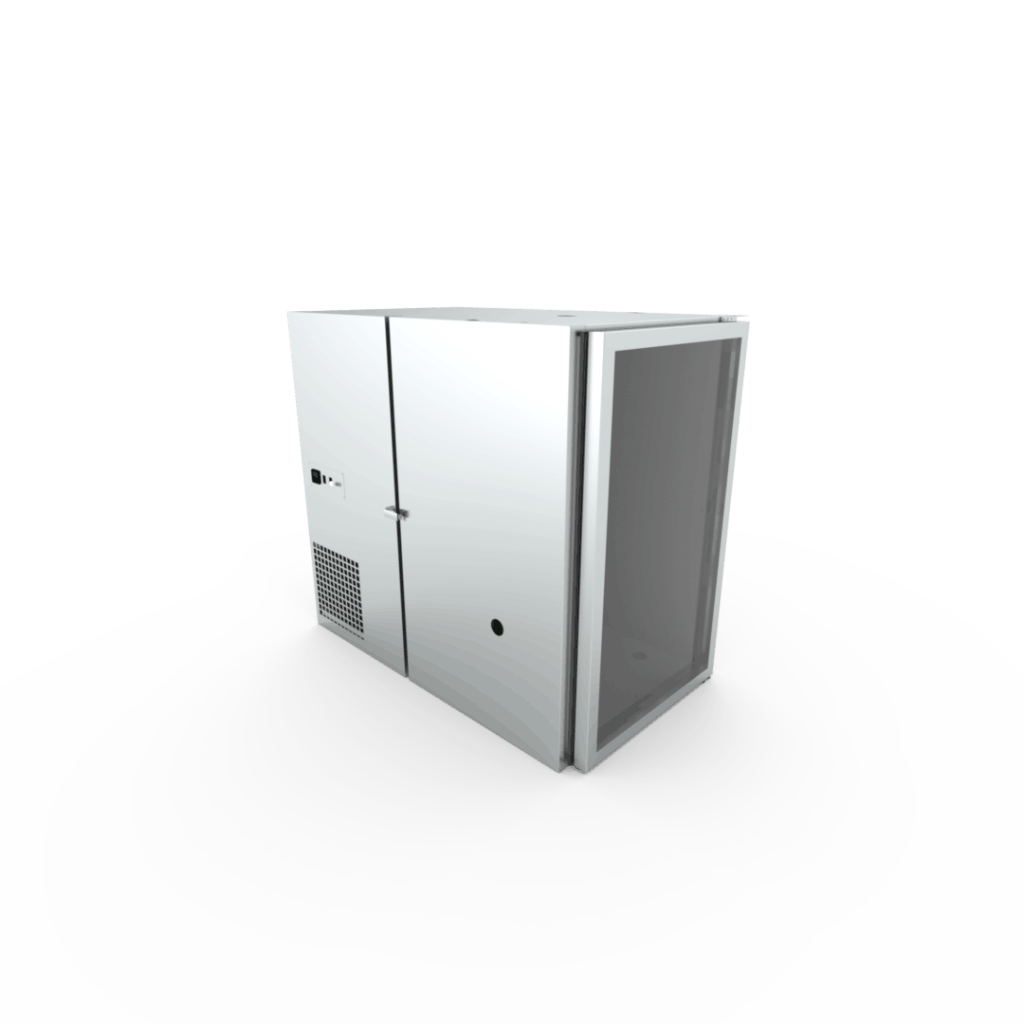

Compression Testing Chamber module FDM PRC30C80

To meet the request of our commercial partner, the FDM R&D department has designed a temperature controlled chamber (obviously with the possibility of adding the humidity option) to be coupled directly to the press.

This means that, for any customer already in possession of a press, we will be able to design and build an independent module around it.

The possibility of creating a customized climate testing module for a press, gives the customer the advantage of performing new tests or adapting to new regulations, without the onerous problem of having to buy a new press.

The FDM climatic customized module for testing materials is hence independent from the press but built around it and interchangeable.

The instrument is divided into two parts, one of power and one of test (module for climatic test), so that, in case of maintenance of the power part, this can be separated from the press without disassemblying procedures.

FDM and customized climatic chambers

The FDM PRC30C80 climatic module therefore has a very important advantage: it can be customized according to the press. The specific features of the outcome, which you can find in the datasheet are totally modifiable according to the different test requirements.

The flexibility and the ability to listen and almost always develop the particular specifications from our customers into a unique product, have made FDM a leader in controlled temperature and humidity environments. Since 1949, we have been manufacturing climatic chambers for all requirements.

Would you like to receive a quote or do you have questions about the product?

Contact us to receive more information about this Product.