Types of Automotive Testing

Automotive is an industry where product testing has got endless applications.

Cars and vehicles in general are an integral part of our daily lives and must guarantee our total safety, for every use and under every circumstance.

And that's not all: safety standards are not only defined by the manufacturers' brands and their sub-suppliers, but also by the regulatory bodies that have to give the green light for type approval and subsequent sale of the final product.

In fact, there are several situations that may require testing in the automotive industry. These tests involve the various components that make up the vehicle, such as:

- bodywork (crash tests, road surface irregularity tests, colour tests)

- engine (cooling, heating, engine oil, fuel, coolant, gas emissions)

- electronic and electromechanical components (such as EMC tests for electromagnetic compatibility 2004/104/EC, 2004/108/EC)

- Specific operation of different parts (steering, wheels, brakes, gearbox, etc.)

Car brands themselves have created their own standards for specific in-house tests, which have become production standards over time.

So, besides the well-known IEC, ISO or ASTM regulatory bodies, we can have a 50451 (Fiat) or a Volkswagen PV 1306.

Environmental Tests for Automotive Applications: Introduction

Among the tests associated with the automotive field, we certainly have various climatic tests, with controlled temperature and humidity.

These tests, as we have already seen for other applications, can concern both the different components that make up the finished product and the finished vehicles themselves.

Automotive climatic tests therefore concern not only the manufacturers directly, but also the suppliers of the individual components that will constitute the car.

In quest’ultimo caso, le prove climatiche riguarderanno dalle schede elettroniche, ai motori elettrici, alle batterie al litio. Le norme più diffuse che regolano questi test climatici, sono la IEC 60068 e la ISO 16750-4 e la IEC/EN 62133, specifica per la batterie.

In addition to these, as we mentioned before, many car manufacturers have developed their own test procedures, homologous to international standards.

In the case of the finished vehicle, however, as these are large products, reference should be made to the walk-in chambers already discussed here.

In both situations, however, the tests share similar characteristics, which in turn the automotive sector shares with the aeronautics , aerospace and military sectors of which we talked here .

But let us now look at the main features of the automotive environmental testing.

Perform

Extreme Testing

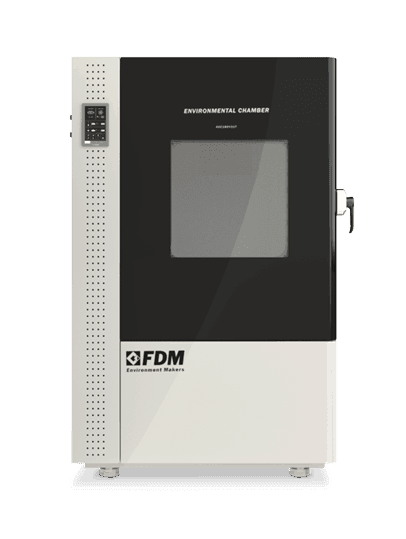

Discover the new series of Environmental Chambers for controlled climate testing

Automotive Environmental Testing: Features

Automotive climate tests take into account the three fundamental variables in these tests: temperature, humidity and lighting.

In most cases, the temperature range is very wide, generally from -40° to 180°.

This range is due to the need for the cars to be operational, without any repercussions, in the different climatic zones of the globe, where they can also be subject to sudden temperature changes (thermal shock).

These temperature ranges contribute to the so-called accelerated ageing tests, which exacerbate the climatic conditions, in order to speed up the ageing process of the EUT.

In order to meet these requirements, the automotive climatic chambers are always equipped with touch screen controllers, which allow automatic temperature cycles to be programmed quickly and immediately.

The uniformity and stability of the temperature must have as low a margin of error as possible, greater than in standard climate chambers.

The same applies to humidity control: a wide range, basically from 10 to 98%, is used to simulate all the possible real-life conditions with which the car, in all its components, will have to deal during its product life cycle.

The ageing process is also simulated by corrosion simulation tests (salt spray test), rain tests and sunlight simulation tests.

Sunlight is simulated using UV lamps, according to standards such as ISO 4892-2, or ASTM D7356.

You cannot find the ideal chamber for your test?

Create your own environment, according to any test requirement

FDM and Environmental Testing for the Automotive Sector

Automotive manufacturing companies are making increasing investments in the field of environmental control, in order to ensure increasingly efficient and safe products.

For example, brands such as Seat have invested 30 million euros in their climate test centre in 2020.

FDM, in the field since 1949, counts among its customers historical brands of the highest quality such as Ferrari and Bridgestone. Here you will find the customised solution we have created for them.

Whether you need to test your tyre, lithium batteries or any component of your car, FDM will always have a solution for your requirement.

Would you like to receive a quote or do you have questions about the product?

Contact us to receive more information about this Product.