If you are reading this article, it means that electronics testing has affected your life even if you don't know it.

In fact, all electronic products - from consumer electronics to components - must pass a rigorous series of tests that guarantee their reliability, safety and performance.

These tests include a wide range of procedures designed to evaluate different aspects of electronic components, from their electrical characteristics to their performance under different environmental conditions. In this article, we will focus specifically on environmental electronic testing, examining their purpose, the main types of testing, and the importance of environmental chambers.

What are Environmental Tests on Electronics for?

Environmental testing of electronics is crucial to determining how devices react to different environmental conditions, such as extreme temperatures, sudden or cyclical excursions, and humidity levels.

These tests help predict the behavior of electronic components in real-world situations, ensuring that they can operate correctly and safely in the most adverse conditions.

The main objective is to preventively identify design defects to improve the reliability of the final product.

difetti di progettazione per migliorare la affidabilità del prodotto finale.Perform

Extreme Testing

Discover the new series of Environmental Chambers for controlled climate testing

Types of Electronics Climate Tests

There are different types of environmental electronic tests, each with its own purpose and field of application.

Below we will see the three most widespread tests that are used both in consumer electronics and in components.

- Burn-In Test: carried out mainly on electronic boards, the Burn-In Test short-circuits all the components of the board through climatic stress. The testing temperature must be carefully controlled, not to be too high and burn the chips, but high enough to simulate particular conditions.

The guidelines for carrying out the test can be found in the MIL-STD-883 standard while for further information on the test you can read here.

- Thermal Cycle Test: The thermal cycle test involves the cyclic heating and cooling of the electronic components according to precise procedures, outlined for example by the IEC 60068-2-14 standard. This test is essential to evaluate the device's resistance to temperature variations and we have explored it in detail here.

- Humidity and Damp Heat Test: humidity is also an environmental factor to take into consideration for the sealing and performance of electronics. The humidity and damp heat test aims to verify just this. We have explored it here. Among the standards that outline it we find the aforementioned MIL-STD 883 and IEC 60068-2-30

The Environmental Chamber for Electronics Testing

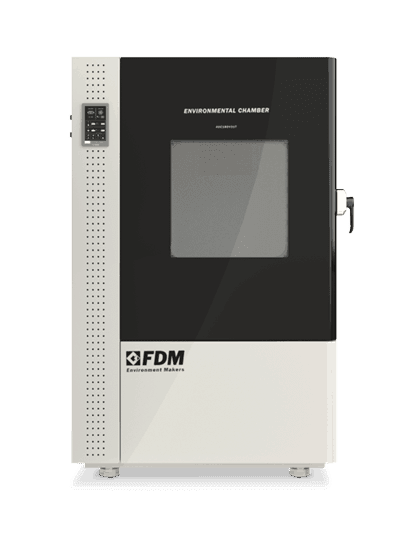

The laboratory instrument for performing environmental electronic tests is called an environmental chamber.

Environmental chambers belong to the family of climatic chambers and are specialized in extreme climatic tests, i.e. those which reach significant levels of both positive and negative temperatures.

The environmental chamber consists of a compartment completely isolated from the outside and equipped with advanced technologies that allow you to set, regulate and monitor precise levels of temperature and relative humidity.

To perform electronic tests, the sample to be tested is placed inside the chamber and temperature and relative humidity values

You cannot find the ideal chamber for your test?

Create your own environment, according to any test requirement

The FDM Environmental Chamber for Electronics Testing

The FDM - Environment Makers Environmental Chamber has all the requirements to carry out the tests we have described in this article.

Its stillFACE controller guarantees precision and reliability in static tests while the revoFACE programmer allows the operator to set a wide range of dynamic tests.

For further needs, please do not hesitate to contact us.

Would you like to receive a quote or do you have questions about the product?

Contact us to receive more information about this Product.