Testing products and materials is essential to ensure their safety and reliability, especially if they are intended for use in extreme environments.

There is no more extreme environment than deep space.

This is why aerospace testing is a crucial phase in the industry. In today's article, we will focus on aerospace testing in the environmental chamber, which is all the tests that concern the impact of the surrounding environment on space vehicles and their components.

What are Environmental Testing Used For in the Aerospace Industry?

Aerospace climate tests are designed to verify how materials, components or systems react to the extreme conditions found in deep space or in the Earth's atmosphere. These tests serve to prevent critical failures and improve the reliability of missions.

For example, a satellite must withstand extreme temperatures that can vary drastically and rapidly.

Similarly, the materials used in probes must tolerate high percentages of humidity before launch, so as not to compromise the internal electronics. Solar radiation is also a crucial factor: coatings and solar panels are essential in the aerospace industry and must be thoroughly tested.

Simulating these conditions before the actual use of vehicles and components allows us to identify any design weaknesses and intervene promptly.

Perform

Extreme Testing

Discover the new series of Environmental Chambers for controlled climate testing

How Does an Environmental Test Work?

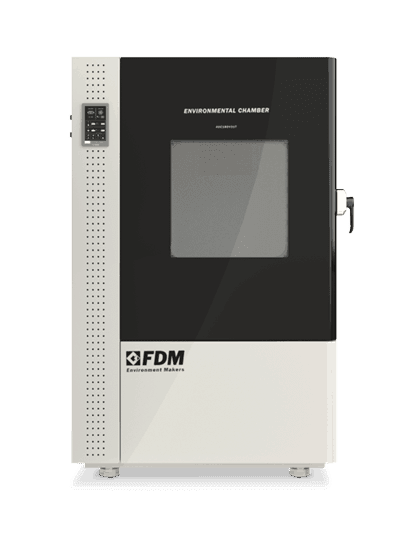

Most environmental tests involve the use of laboratory instruments called environmental chambers. Environmental chambers are part of the larger family of climatic chambers: hermetically sealed compartments within which a series of environmental parameters can be altered and monitored at will. Environmental chambers are the version of climatic chambers specialized in extreme tests, such as aerospace testing.

Let's see what are the most relevant environmental parameters in aerospace testing:

- Temperature: an environmental chamber can go from extremely low temperatures to very high temperatures, and both are relevant for aerospace testing.

- Humidity: the system can control the humidity level to evaluate the effects of condensation or corrosion on materials.

- b>Solar illumination: Environmental chambers can be equipped with lighting systems that emulate the spectrum of sunlight to study the degradation of materials and coatings.

Tests can be performed on individual components or entire structures.

For tests on entire spacecraft or large structures, walk-in chambers are used: that type of large climatic chamber that you can actually walk into. In this case, they are so large that they allow the entry not only of humans but of entire spacecraft.

International Standards on Aerospace Testing

Like all tests on products and materials, aerospace tests are also governed by a series of internationally recognized standards.

Here are the main ones.

- ISO 14644: concerns the classification and management of controlled environments, essential for maintaining ideal conditions during tests.

- ISO 11224: provides guidelines for simulating humidity conditions.

- NASA-STD-7001: a specific standard for exposure tests to solar radiation and thermal vacuum.

You cannot find the ideal chamber for your test?

Create your own environment, according to any test requirement

The FDM Environmental Chamber for Aerospace Testing

For over 70 years, FDM - Environment Makers has been recognized as a leading company in the climate simulation sector.

Our environmental chambers reach extreme temperatures - both up and down - and reach relative humidity levels close to saturation. They are therefore suitable for carrying out the aerospace tests indicated above.

Do not hesitate to contact us to find out more.

Would you like to receive a quote or do you have questions about the product?

Contact us to receive more information about this Product.