Humans have used concrete for the past 5,000 years to build monuments that would stand the test of time.

What Is Concrete?

The binder is typically Portland cement; it holds the matrix together.

The chemical composition makes it durable, strong, and gives it the ability to lose plasticity and gain dense after the addition of water.

However, the greatest threat to concrete structures is the carbonation process.

What Is the Carbonation of Concrete?

The rate of carbonation depends on many physical characteristics, such as:

On-site preparation Production and protection The design of the structure

Environmental factors, such as heat, rain, snow, and humidity, also play a role in carbonation.

What Does Carbonation Effect?

There is some good news, though.

Carbonation also increases the compressive and tensile strength of concrete . The key is to find the right balance. To do this, you need accelerated carbonation tests.

What Is Accelerated Carbonation Testing?

In simple terms, this test is nothing more than a in-depth investigation to accelerate carbonation in a controlled environment .

It is a way for concrete professionals to test their product and determine its ability to last under certain conditions. This test is performed by checking the corrosion resistance. Needless to say, how a correct diagnosis of any issues can be fundamental on the safety and prevention sides.

-

- The concentration of CO2 gas — This is an especially important factor for concrete used in cities with large amounts of pollution

- Humidity — It is preferable for humidity to be at 50%-70%. There is less water with higher humidity. Water inhibits CO2 diffusion when it has higher concentration.

- Temperature — In hotter environments, there is a higher carbonation rate

- Water to cement ratio — this determines the pore system of the concrete and degree of hydration.

Porosity and permeability

Standards and Procedures for the Carbonation Test of Concrete

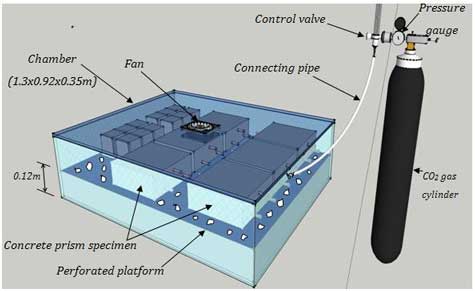

CO2 levels at 4% Relative humidity levels at 65% Temperature setting at 20°C Active CO2 control An efficient circulation fan A reference mix Calibration and adequate logging of results

fig.1: Experimental set up for accelerated carbonation

Remedies for the carbonation of concrete

The only way forward is to try to prevent the issue by making all the necessary tests before the concrete is produced.

How to Find the Right Testing Chamber

Find below a few suggestions to understand what the main assessments during the investigation with a test chamber for concrete are.

You will have to measure different variables for every type of concrete to be tested. You will also have to apply different values to these variables based on where the concrete gets used.

For example, you will have to increase the amount of humidity to test concrete used in Florida vs. Kansas. You will also need to factor in the year-long heat and extreme summer heat Florida has vs. the cold of Kansas winters. You will need a testing chamber that allows making variations as the experiments demand them. You will also need one that is durable. The concrete carbonation test procedure is an ongoing process.

We Can Help You Find Your Ideal Chamber

You can choose between various sizes along with two different controllers, depending on whether you are running stability or dynamic testing.